5.0 Based On 27 Reviews

Ottawa's Best LIFETIME Warranty

1-Day Floors Vs. 2-Day Floors: Why We Chose Quality Over Speed

VS

Why the Differences DO Matter

We’ve all heard the saying, “Rome wasn’t built in a day.” It’s a reminder that quality work takes time and shouldn’t be rushed. The same holds true for garage floor coatings.

When comparing a traditional two-day garage floor installation to the rising popularity of one-day polyurea systems, an important question comes up. Is faster really better?

To answer that, it’s essential to look at the differences in materials, application methods, and long-term durability. While both may look similar at first, the quality and lifespan can be worlds apart. The real question is whether one-day systems truly benefit homeowners or simply make life easier for the contractors installing them.

The Key Components Of A Professional Epoxy Floor

Before diving into the differences between one-day and two-day systems, it’s important to understand the core components of any high-quality epoxy or polyaspartic flooring system. These include surface preparation, coating materials, and installation expertise.

Surface Preparation

The foundation of a long-lasting floor starts with properly preparing the concrete surface. This involves mechanically grinding the floor to achieve a Concrete Surface Profile (CSP) of 2, 3, or 4 using industrial-grade diamond grinders. These powerful machines remove surface contaminants like old coatings, oil, dirt, and road grime while also opening the concrete pores to create a mechanical and chemical bond with the coating.

A crucial part of this step is repairing any cracks, chips, or imperfections in the concrete. Restoring the surface ensures the coating adheres properly and prevents future failures. The level of repair needed depends on the condition of the concrete, and various polymer-based repair materials are used to reinforce and strengthen damaged areas.

Without proper surface preparation, even the best coatings won’t stand the test of time.

The Role of Materials

The second key component of a high-performance floor system is the quality of materials used. Unlike DIY kits sold at home improvement stores—often water-based or low in solids—industrial-grade coatings are formulated for superior durability and adhesion.

Professional coatings include epoxies, polyaspartics, polyureas, and urethanes, all of which are two-part systems. These consist of a resin (Part A) and an activator (Part B) that, when mixed, trigger a chemical reaction.

This reaction creates a hardened, durable surface that bonds effectively to the prepared substrate, ensuring long-lasting protection and performance.

The Importance of Installation Expertise

The final—and arguably most crucial—component of a high-quality coating system is the expertise of the installation team. Even the best materials won’t perform as intended if they aren’t applied correctly. Experienced professionals are trained to handle the unique challenges that can arise during surface preparation and application, ensuring a flawless finish.

A key factor they consider is Moisture Vapor Emissions Rate (MVER), which affects how well coatings bond to the substrate. This involves assessing variables such as concrete temperature, pH levels, ambient humidity, and dew point—all of which impact long-term durability and adhesion.

Understanding The Full-Broadcast Coating Systems

One of the most widely used garage floor coating methods is the full-broadcast system, a technique trusted by coating professionals for its durability and aesthetic appeal. This system involves applying materials at specific coverage rates based on manufacturer guidelines and installation techniques to achieve an optimal finish and mil thickness.

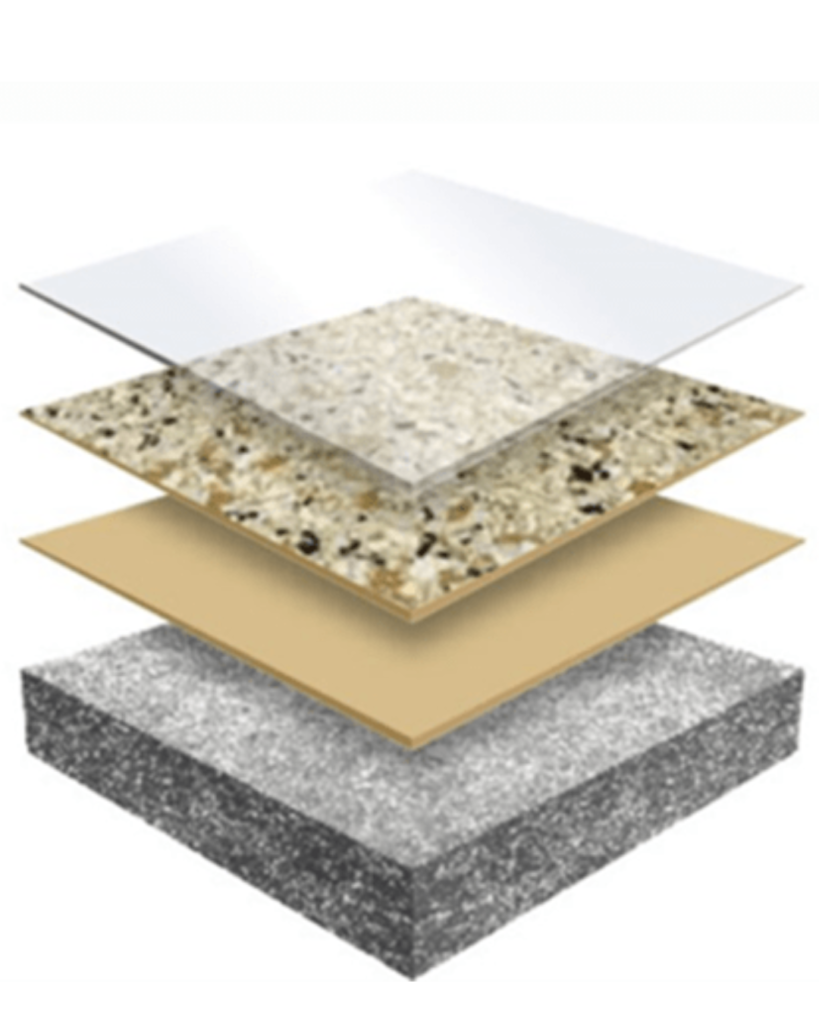

Components of a Full-Broadcast System:

- Base Coat – Bonds directly to the concrete, providing the foundation for the coating.

- Broadcast Medium – The decorative layer, typically consisting of polymer flakes, quartz, or sand, adding texture and visual appeal.

- Top Coat (Clear Coat) – Seals and protects the surface, ensuring longevity, stain resistance, and durability.

Why the Base Coat Matters Most

When evaluating the quality and lifespan of a coating, factors like material type, application thickness, and installation methods play a critical role.

However, the base coat is the most important layer, as it determines the adhesion, durability, and long-term performance of the entire system. Without a properly bonded base coat, even the best-looking coatings won’t stand the test of time.

Understanding The Product Components

Both one-day and two-day coating systems rely on polyaspartic top coats, a best-in-class material known for chemical resistance, abrasion protection, and UV stability.

This makes polyaspartics a top choice for both industrial and residential applications.

However, the key difference between these two installation methods comes down to the base coat, which is responsible for bonding the coating to the concrete.

Base Coat Comparison: One-Day vs. Two-Day Systems

🔹 Two-Day Systems – Use a high-solids or 100% solids industrial-grade epoxy as the base coat. This creates a stronger bond, providing superior durability and resistance to moisture and heavy wear.

🔹 One-Day Systems – Use a polyurea base coat, which cures quickly but lacks the same level of adhesion and long-term strength as epoxy.

While both methods feature durable polyaspartic top coats, the base coat material determines the overall longevity and performance of the floor—and that’s where the two-day system comes out on top

Epoxies

Epoxies have been around since the 1950s and are widely recognized for their exceptional adhesion strength and durability. These qualities come from epoxy’s chemistry, which allows it to cure slowly and penetrate deeper into the concrete substrate, creating a superior mechanical bond.

One of epoxy’s biggest advantages is its ability to be applied at a thicker mil rate (15–50 mils), which helps smooth out uneven, damaged concrete while adding strength, impact resistance, and longevity. It also performs better in high-moisture environments, making it a go-to option for industrial and commercial applications.

Industrial-grade epoxy—not the DIY kits from big-box stores—is the standard in factories, warehouses, and airplane hangars because it withstands the harshest conditions. In fact, “epoxy” has become a catch-all term for many polymer coatings, though they are not all created equal.

Advantages of Epoxy Coatings:

✔️ Longer cure time = deeper concrete penetration

✔️ Unmatched adhesion & impact resistance

✔️ Performs well in high-moisture environments

Disadvantages of Epoxy Coatings:

⏳ Longer back-to-service time

☀️ Lower UV resistance—can fade or yellow over time

🔨 Requires aggressive surface prep for proper bonding

Polyureas

Polyureas are a newer advancement in polymer coatings, having been around for over two decades. Initially designed for metal corrosion protection in pipelines, storage tanks, and water towers, they are known for chemical resistance and ultra-fast curing times.

Traditional polyureas cure almost instantly, making them ideal for vertical surfaces but more challenging for floor applications. Over time, manufacturers modified polyureas to create polyaspartics, which have a longer working time and are now widely used as premium top coats due to their UV stability, abrasion resistance, and chemical durability.

One major downside of using polyurea as a base coat is its low moisture tolerance. Unlike epoxy, which forms a strong bond even on higher-moisture concrete, polyurea struggles with adhesion issues if the surface isn’t perfectly dry. This increases the risk of delamination and peeling over time.

Advantages of Polyurea (Polyaspartic) Coatings:

✔️ Superior chemical and UV resistance—won’t fade or yellow

✔️ Fast cure times—quicker return to service

✔️ Excellent abrasion resistance

Disadvantages of Polyurea (Polyaspartic) Coatings:

⚡ Cures too fast to deeply penetrate concrete

🚧 Higher risk of peeling if moisture is present

🎨 Must be applied in thin layers—limits overall system thickness

One-Day vs. Two-Day System Claims – What’s the Truth?

If you’re considering a full-broadcast epoxy floor, you’ve probably seen a lot of claims about one-day vs. two-day systems. Let’s clear things up so you can make the most informed decision.

Claim: Industrial Epoxy is Old Technology.

Reality: TRUE. And That’s a Good Thing.

Industrial epoxy has been around for decades, and for good reason—it works. While residential garages might seem low-maintenance, they’re actually one of the most demanding environments for coatings. Floors need to withstand heavy vehicles, constant wear, and extreme temperature changes, from below freezing in winter to over 150°F in summer.

Epoxy’s slow curing time allows it to penetrate deep into the concrete (3-6 mils), creating a strong, permanent bond that resists peeling and delamination. Polyurea base coats, on the other hand, cure too fast to soak in properly, often resulting in weaker adhesion and a higher risk of failure over time.

Despite advancements in polyurea technology, the coatings industry still trusts high-solids industrial epoxy for its durability and adhesion.

That’s why leading manufacturers, commercial contractors, and industrial facilities continue to rely on epoxy as the foundation of their coatings.

At the end of the day, there’s no one-size-fits-all solution. But when durability is the priority, epoxy remains the go-to choice—not what’s fastest for the installer.

Claim: Epoxy is Inferior to Polyurea.

Reality: Both TRUE and FALSE.

Polyureas and polyaspartics do have advantages over epoxy, such as superior UV resistance, chemical resistance, and faster cure times. These qualities make them an excellent top coat for long-term protection.

However, when it comes to bonding directly to concrete, polyureas were not originally designed for adhesion strength. They were created for thin-mil coatings on non-porous metals, not highly absorbent concrete.

One-day system installers often highlight polyurea’s flexibility, but industry experts agree that for garage floors, permanent adhesion is far more important than flexibility.

Epoxy has been the gold standard for concrete adhesion for decades, and it remains the preferred base coat for experienced coatings companies. The two-day hybrid system—an industrial epoxy base coat with a polyaspartic top coat—offers the best of both worlds: deep penetration, unbeatable adhesion, and long-term surface protection.

The biggest reason one-day installers push polyurea-only systems? They’re faster and easier to install. Many companies claim to offer 15-year or even lifetime warranties, but considering one-day polyurea systems are relatively new to the market, how can they confidently promise decades of durability?

At Royal Coatings, we refuse to gamble with your floors. That’s why we stick with our two-day hybrid system, backed by Ottawa’s only lifetime warranty—because quality takes time, and we do it right.

Claim: One-Day Polyurea Floors Are "Stronger Than Epoxy."

Reality: FALSE.

We see this claim all the time—one-day installers boasting that polyurea base coats are “20 times stronger” than epoxy. But here’s the thing: where’s the proof? There’s no factual data to back it up, and when you dig deeper, the claim just doesn’t hold up.

Let’s break it down.

First, which type of epoxy are they comparing it to? Are they talking about DIY epoxy kits from home improvement stores—the kind that’s watered down and easy to apply but lacks serious durability? Or are they comparing it to industrial-strength epoxy, the stuff trusted in airplane hangars, factories, and warehouses? Because those are two completely different products.

Cheap DIY epoxy kits don’t bond well to concrete and are prone to peeling and failure. That’s NOT what we use. At Royal Coatings, we use a high-solids, industrial-grade MVB epoxy base coat that soaks deep into the concrete, creating a permanent bond. It’s built to last, not just look good for a few months.

The reality is, you can’t just say one polymer is “stronger” than another without defining what “strong” actually means. When measuring strength, you have to look at:

- Bond Strength (how well it sticks to concrete)

- Compressive Strength (how much weight it can handle)

- Flexural Strength (how much it bends before breaking)

- Tensile Strength (how much force it can take before pulling apart)

And here’s the most important part: none of those measurements matter if the floor doesn’t stay bonded to the concrete.

That’s why Bond Strength is king. A coating is only as strong as its adhesion to the surface, and epoxy has been proven—time and time again—to bond deeper and more permanently than polyurea. In fact, in strength tests (ASTM D-7234), high-quality epoxy bonds so well that the concrete itself fails before the coating does. That’s the level of durability we stand behind.

So, are polyurea base coats really “20 times stronger” than epoxy? Nope. If anything, epoxy has the stronger, longer-lasting bond.

That’s why Royal Coatings sticks to what works—our two-day hybrid system with an epoxy base and polyaspartic topcoat. It’s not about what’s faster—it’s about what’s built to last. And that’s why we’re the only company in Ottawa offering a lifetime warranty on our floors.

Claim: Polyurea Floors Are Just as Thick as Epoxy/Polyaspartic Systems.

Reality: FALSE.

Some one-day flooring companies claim their coatings are just as thick as two-day systems—or they just don’t mention thickness at all. But here’s the truth: thickness matters, and polyurea base coats are significantly thinner than industrial epoxy base coats.

If a coating is too thin, it won’t hold up to everyday garage use. If it’s too thick, it can become brittle. Getting the right thickness at every stage is key to durability and longevity.

🔹 Polyurea base coats are applied at 4-6 mils thick (250-375 sq. ft. per gallon).

🔹 Epoxy base coats are applied at 10-16 mils thick (100-160 sq. ft. per gallon).

That’s a huge difference—polyurea base coats can be up to 50% thinner than epoxy-based systems, leading to:

- Inconsistent coverage (thin base coats don’t hold flakes properly).

- Less impact resistance (thinner coatings mean less protection).

- Weaker long-term durability (less material = shorter lifespan).

A coating’s compressive strength and flexibility mean nothing if it isn’t applied at the right thickness. That’s why professional companies like us use precise formulas to ensure the correct Dry Film Thickness (DFT) for long-term durability.

At Royal Coatings, we don’t cut corners—we build floors to last.

Claim: Polyurea Floors Cure Faster.

Reality: TRUE (But Speed Isn’t Everything).

One-day polyurea floors do cure fast—typically allowing full use within 24 hours due to their thinner application and rapid chemical reaction. In contrast, our two-day hybrid system lets you walk on your floor the next day and park your car a few days later.

So, if you absolutely need a floor in one day—like for a commercial space with constant foot traffic—a polyurea system might be a fit. But for homeowners who want the longest-lasting, most durable option? Our hybrid system with an industrial epoxy base and polyaspartic topcoat is the way to go.

Think about it: if one-day systems were truly better, why don’t industrial coatings contractors—who handle massive factories, warehouses, and airplane hangars—use them as their go-to option?

Claim: Epoxy Can’t Be Installed in Cold or Hot Weather.

Reality: FALSE.

Some one-day flooring companies claim epoxy can’t handle extreme temperatures, but let’s break it down.

First off, garage floors aren’t exposed to direct weather like outdoor concrete, so their temperature stays relatively stable between 35-75°F year-round in most places. This means epoxy installation isn’t as limited by seasonality as some claim.

Second, coatings manufacturers already have solutions for extreme temperatures.

Whether it’s a cold-weather or warm-weather hardener, professional installers (like us) can adjust the curing process to ensure a flawless, long-lasting bond—without sacrificing durability.

So, unless you’re planning to install your garage floor in the middle of a snowstorm, temperature isn’t an issue for a properly installed epoxy system.

Final Thoughts

Science and chemistry both point to one conclusion: combining the best attributes of each product results in the best floor. Industrial-strength epoxy remains the superior base coat for full-broadcast garage floor systems because it forms a permanent mechanical and chemical bond with the concrete.

Polyaspartic, on the other hand, shines as a top coat, offering exceptional abrasion, chemical, and UV resistance to protect the system.

Kelly Otts, Senior Sales Representative at Sika—a global leader in industrial coatings—puts it best:

“Using a hybrid system of industrial-strength epoxy as a base coat and polyaspartic as a top or clear coat is the preferred industrial methodology. These systems leverage the best of both materials to create a durable, chemical-resistant, abrasion-resistant, and UV-stable floor—trusted by industrial, commercial, and residential contractors for decades.”

Like countless industry professionals, we believe in doing it right—which is why Royal Coatings exclusively installs two-day hybrid systems with a thicker epoxy base coat and a polyaspartic top coat. This combination ensures maximum durability and longevity.

The reality?

Quality takes time. And while other companies rush through one-day installations, we’re here to build something that lasts. Because as they say—Rome wasn’t built in a day. And neither should your garage floor.

Get In Touch With Us Today For Premium Concrete Coatings

We guarantee top-quality products and services, using materials specifically engineered for maximum durability and performance.

Superior Epoxy Floors for Homes & Businesses—Unmatched Durability, Style, and Value.ite.

COPYRIGHT © 2025 Royal Coatings Of Ottawa | ALL RIGHTS RESERVED.